Blog / How to Ensure You Deliver Fabrication Projects On Time and On Budget

How to Ensure You Deliver Fabrication Projects On Time and On Budget

Fabrication Projects

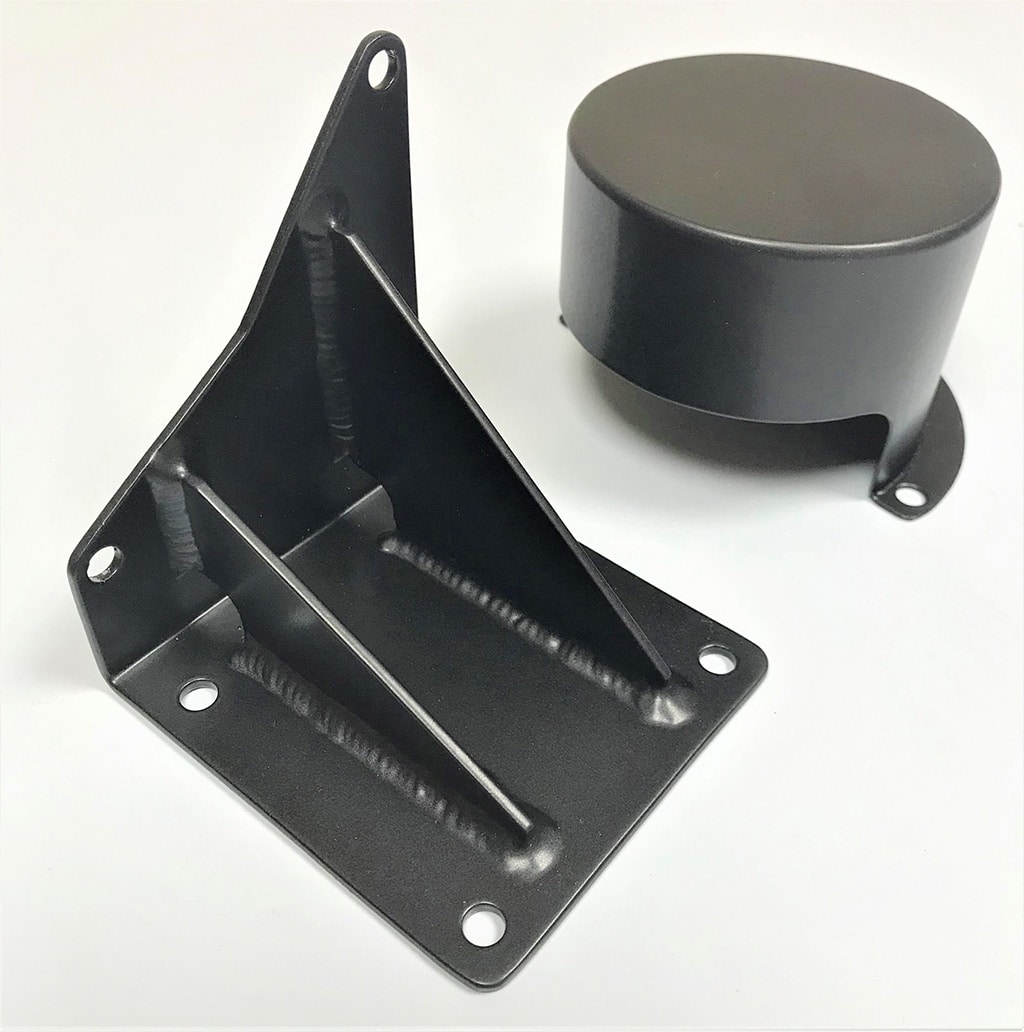

Fabrication refers to the shaping, cutting and molding of metal into finished products. Usually these fabrications make their way into end-users goods, such as automobiles, aircraft, household appliances and some disposable items. Popular metals for fabrication including tin, iron, nickel, steel and many others.

Businesses that deliver metal fabrication services are called fab shops. Usually, they bid for projects based on drawings they receive from clients. Following a short process, clients then choose the fabricator they want to complete their project.

Once a client confirms a sheet metal manufacturing project with a fab shop, the fabricators enter the planning phase. This part of the process involves ordering the necessary raw materials, programming CNC machines, and subcontracting various tastes as required.

If you have any questions about our specialist welding services or want to discuss a specific project then please contact us on 024 7661 0778, or via email at sales@mplfabrications.com. Our expert engineers are ready and waiting to explain exactly how we could deliver the sheet metal components you need.

Why Delivering Fabrications On-Time Matters

Delivering sheet metal fabrications on-time matters because clients usually have tight production schedules of their own. A small delay could wind up costing them unacceptable amounts of money or even lead to the shutdown of a line.

From the perspective of the fab shop, it is also an important issue. Failing to deliver a project on-time could leave the client to go elsewhere. If a large client chooses a rival, it could even threaten the survival of the entire business.

Delivering a project on-time, therefore, is essential. But it can also get a little stressful, especially as your deadline approaches.

The trick here is to implement state-of-the-art project management tools. By structuring the way in which you approach each job, you can maximize your efficiency and avoid having to rush towards the end.

Let’s run through the various stages:

● Planning: For successful planning, you require a thoughtful appraisal of the project’s scope. Start with a definition of the various stakeholders and their responsibilities and then move onto identifying project risks and things that might go wrong along the way. Following that, consider other aspects, such as your site requirements, funding requirements and the financial impact of fulfilling the order.

● Design stage: The next step involves putting together an agreed-upon design. Effective management at this stage means reviewing key deliverables, setting time aside for functional testing, and ensuring that any fabrication is feasible, given current tooling.

● Schedule management: The third step is to establish a timeline for delivering on the project’s key deliverables. Critically, it should detail how you will allocate fab resources to avoid missing deadlines. Where possible, make your schedules as comprehensive as you can so that you immediately know if you are falling behind.

● Project management software: Lastly, software makes it easier to engage in effective time management, particularly when clients submit complex projects with many variables. Having a work breakdown structure allows you to more effectively marshal your resources and allocate labour to the places it’s needed the most.

Why Delivering Fabrications On-Budget Matters

Clients often have razor-thin margins. And so they depend on their suppliers to deliver items on-budget. If they don’t, then it can be challenging for them to turn a profit on secondary products from which metal is an input.

From your perspective, delivering on-budget matters for a second reason: the fact that you would like to be able to deliver at a price that will generate profits for your business. If your costs grow too much, then providing the fabricated metal will eventually become infeasible.

Here are some of the methods you can use to deliver fabrications on-budget:

● Establish a budget: The first part of the process is to establish a budget that provides a realistic estimate of the cost of carrying out the work the client requests. It should take into consideration things like current market conditions, the complexity of the project, and that stages involved in making it a reality. Only approved changes should be made to the budget.

● Engage in cost control: Cost control is a systematic process that involves ensuring that expenses remain minimal at every stage of the production process. It requires a thorough understanding of the scope of the fab project, thoughtful planning and execution of the work and respecting people’s roles when solving the inevitable issues that arise.

● Budget management: Budget management is usually part of the design phase. Here you plan out how much each part of the project is likely to cost and identify potential areas where cost-creep might come into play. By budgeting in advance, you can give clients a realistic idea about how much their projects are likely to cost them overall.

Delivering fabrication projects on-time and on-budget, therefore, is possible, so long as you engage in the correct project management practices. Ready to take the next step? See how MPL Fabrications have bought our client's designs to life